| Published in the August 2001 Issue of Anvil

Magazine

Note: Images and captions are at the end of this article. The metal rings out with each blow: one to the slot punch to mark the spot, two more to drive it in. Then he lets loose on the drift to size the hole. In the last heat, he holds one end of the stock in hand and cools the tip of the other end in water. He then taps it, gently, on the anvil to open up the hole...and drifts it again to get the exact size of the hole right. What is immediately tangible about Jerry Hoffmann, when he is working, is the precision and economy of his hammering. No motion is wasted. Every blow seems as if backed by a specific intention. When questioned about it, he will tell you that you need only use the number of strikes required for the job, in the interest of saving your joints. But there is more going on here than that alone. There is an intensity, a kind of concentrated intent. Jerry is extremely focused mentally, and the end result is evident in his work. He speaks of beginning with the end in mind, of knowing your intention for any given stroke in advance. The gate that he is working on is just the right blend of old and new; it is not as extreme as many modern pieces are. It's just a little bit retro, almost in the tradition of art nouveau. Conceived and built as a fundraiser for the 2000 A.B.A.N.A. Conference, it took Jerry and members of the Blacksmiths Association of Missouri four days (500 hours) of forging to make it, and two weeks to put it together. Forged of mild steel and pre-hung with an in- ground hinge system, it weighs a total of 1800 pounds. Because the rounded bars of the top rails are gradually curved and not a true circle, each hole needed to be at a different angle. The way they were made was by drifting the holes straight, then using a die grinder to adjust the angle. There was also a fine tolerance variance in the hole placement that made putting the whole piece together a bit of a challenge. Jerry emphasized the importance of keeping the punches sharp so they don't drag more metal into the cut, the way they do when dull, potentially distorting the measurements of the piece as a whole. For Jerry Hoffmann, the creative process of design and implementation from start to finish consists of seven sometimes-overlapping phases: conception of an idea, making a drawing, modeling, estimating measurements, creating a test piece, forging the piece and putting it all together. He uses drawing to enhance his ideas because, to his way of thinking, just having an idea in your head is not enough. In making an actual model, like an architect might do, the complications become concrete. It is in implementing an idea that the flaws become apparent. If you are designing something completely flat, making a two-dimensional drawing is quite helpful, but even a gate is really a three-dimensional object, and must be conceived that way. A seemingly mild-mannered person, Jerry looks more like a professor than a blacksmith. To look at him you wouldn't expect to see him swinging a hammer, much less building these architecturally dramatic structures, inspired by an urge to delight the eye and relying heavily on geometry for their design. Jerry and his wife Janelle reside in Missouri, where they run Hoffmann Publications. They publish two how-to magazines, The Blacksmith's Journal and the latest addition, Iron & Wood. Jerry went to Kansas University and earned a degree in graphic arts. He knew from the time he was in grade school that he wanted to do some kind of art. His father did carpentry, so from an early age he picked up the use of a hammer by helping his father with carpentry projects. He has also been drawing since he was a kid. Jerry, as well as many other blacksmiths, believes that the ability to draw makes a major difference in the design aspect of the work. "One of the advantages of being able to draw is that you can sell your piece before you make it, by helping the customer visualize the finished product," says Jerry. Another advantage is the ability to make accurate renditions of a piece the actual size of the finished product, which can take a greater margin of error out of the measurements. Jerry uses a technique for working out forging sequences without actually heating and forging the stock. For Jerry, it is essential to build a piece, at least in miniature, before the final piece is built. Over the years he has saved piles of the kneaded erasers commonly used for drawing, the kind that you can mold like silly putty. He uses this very malleable, easy-to-work substance to test ideas. He uses wooden blacksmith tools to simulate the actual forging process, then does a full- size drawing, if at all possible, using white charcoal pencil on a steel surface. He makes most of his own tools. The metallurgy he knows was mostly garnered from local blacksmithing meetings. He uses white charcoal pencils to mark the iron, because it doesn't wash off when wet. At this point in the game, he does no commission work. Most of the work he does he makes for himself to use for demos, videotapes or for subject matter for his publications. Some of it gets sold, some does not. Either way it's okay with him, which allows him the relative luxury of following his own muse and pretty much letting go of the results. Naturally this creates a certain freedom in the creative process, which is important to him. Without the constraint of having a buyer physically requesting how the piece should look or how fast it needs to be completed, Jerry finds the free flow of ideas more abundant. Jerry got into blacksmithing seemingly by accident. His wife bought a horse. When the farrier came to shoe the horse, Jerry was intrigued and decided he could see himself doing that, so he did an apprenticeship and ended up working as a farrier for 10 years. In the context of making shoes, Jerry learned how to do some basic forging and forge welding by making shoes. He participated in local competitions, honing his forging skills. His love of architectural design eventually led him into the business of making gates, railings and hardware. He has been self-employed ever since and has been blacksmithing now for 24 years.

When asked what driving principles guide him in the design process, he expresses

himself in artistic terms rather than in terms of the mechanics of design.

Jerry says, "Form feels good. Kind of like the way that certain aromas smell

good." With regard to major influences on his work, he admits to an enjoyment

of art nouveau, although he hesitates to nail himself down to any specific

style as particularly dominant. His design goal is cohesive with what he

knows of engineering: the simplest design is often the most functional, so

in the quest for functionality, he seeks simplicity. By adhering to the principle

that form follows function, Jerry makes the best possible use of subtlety

to create structures with clean lines and enduring impact. |

|

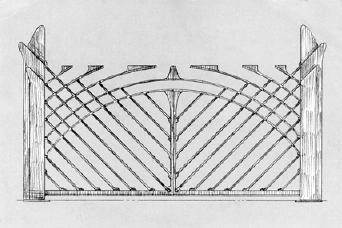

| Driveway gates |

|

| Drawing of the driveway gate on the opposite page |

|

For detailed photos of the gate see "Abana Conference 2000," Anvil Magazine, April 2001 |

|

| Jerry Hoffmann at the 2000 ABANA Conference doing a demo on how the gate was forged |

|

| The finished gate displayed at the ABANA Conference |

|

| Return to the August 2001 Table of

Contents

Return to the Blacksmithing Articles page

|

|