Published in the September 2001 Issue of Anvil Magazine

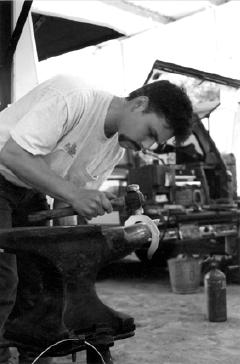

Image: Glue-on shoe job by racetrack farrier Don Reed of Arcadia, California The competition of this year's Northern California Classic (NCC), put on by the Western States Farrier's Association (WSFA), began with a symphony of sights and sounds. A rapid succession of light taps came from somewhere to my left. Behind them echoed a series of dull thuds, while off to my right I could hear mighty clinging blows and happy ringing sounds, all pitched against the deep-throated background roar of the forges. Looking across the shade of the huge covered arena at the Placerville Fairgrounds, I could see heat waves rising. The smell of coal and propane, as well as the gritty odor of hot steel, met my nose. This, along with the visual delight of brightly glowing forges and forms of bodies in motion, meant the competition was on, and the men and women put everything they had into their craft. It's fun to take a moment to be poetic about what we do, and no better place to pause and smell the forges than at the NCC. Farrier Michael Tannehill's two dogs didn't mind the excitement as they lay placidly napping, curled up under his rig, beneath a Nevada "HOOVES" custom license plate. Not the heat, nor the hammering, nor the loudspeaker with announcer Don Gustafson's commanding voice (who also announced the contest at Calgary this year), disturbed their dreams. The Walla Walla Community College from Washington State sent an entourage of students, creating-quite literally-a hot corner of the arena, with five forges blasting at once. The San Diego Farriers Association sent a contingency as well, and it appeared that they were thoroughly enjoying the event. All in all, there were 47 competitors from four states, and attendees from six states, including Rollie Gallego from Hawaii. The fairgrounds at Placerville were picturesque with a wisteria-draped arbor, where an outdoor luncheon was served daily. The food was delicious and was included in the price of the event. Talk about a bang for your buck, the NCC delivered! Thanks to the generous sponsors, Capewell/St. Croix, Thoro'Bred, and numerous others, the event was an absolute bargain. Certification. Contests. Marketplace. Meals. Happy hour. Banquet. Auction. Top national clinicians. Lectures. Demos. Hands-on forging instruction. Small groups sitting around talking into the wee hours...this event was educational, enjoyable, and first class; it was also a family affair, in the broader sense of the word, since many families spent it as their vacation. How many eagle eye contests can boast final rounds with contestants wearing swim trunks and working on a stall jack in the shallow end of a swimming pool? And when the WSFA Board of Directors were spontaneously pitched into the pool, the excitement was almost too much. This is the NCC, a chance to hang with comrades, meet new associates, and take a much-appreciated break from everyday horseshoeing. During the lectures, judge Shayne Carter told his story of growing up in the Salt Lake City area and apprenticing with his father. By age 11, he was earning $6 per shoe job; in high school, he earned $12 per shoe job. Shayne told of his neighbor, a young Michael DeLeonardo (currently re-elected President of the WSFA and former AFA president), fresh out of shoeing school, who suggested Shayne join the newly formed American Farriers Association. Michael encouraged Shayne to continue his lifelong pursuit of knowledge in the craft of farriery. "Stay true to the white line and the horse's conformation," Shayne reminded, as he spoke about gathering up a horse's foot through shoeing. "Experience is something you cannot teach." Shayne also pointed out that "Shoeing is changing. We are demanding more out of our horses, and our clients are demanding more out of us. Basically, we've bred good feet out of horses, which makes our job even more challenging than it used to be." Alice Johnson, who was one of the judges, told a cute story about being taught to make grilled cheese sandwiches with her forge years ago, by none other than Bruce Daniels. Alice gave a slide presentation and lecture regarding her perspective on shoeing. She emphasized shoeing for a horse's particular stance, or posture, and how we need to check and see how the horse stands. Is he standing square, settled into his fetlocks, forward, or underneath? "Do we shoe horses for the wash rack or for the job he does?" asked Alice. "Horses do best when they are most comfortable, and they are most comfortable when they stand squarely underneath themselves. That's why we must check their posture and stance. The horse will compensate for his conformation to get his leg back underneath himself as best he can."

Alice put her trimming to the test and showed slides of long-footed horses

whose posture she changed merely by trimming-both for good and for bad. It

was a demonstration of how trimming affects the horse's stance. To test this

for yourself, try using duct tape to add a wedge pad as a shim, medial or

lateral, then wedge heel, then toe, and see how the foot loads and the horse

stands with all these configurations. There are many variables and possible

perspectives. Check how the foot loads for stance and comfort, as well as

how the fetlock and hock load, whether they are even, or if they fall to

the medial or lateral side. Alice likes to leave the bars weight bearing,

although she trims out the seat of the corn. Check for separations along

the hoof wall and white line. The ideal is a tight white line with no

separations-a "happy foot."

Image: The Department of Transportation approved propane tank on Jim Halverson's rig Also, wet or dry environment affects the feet and can be a wake-up call if the horse cannot handle the changes. In a wet environment, a foot with excess length has more flares and distortions. In a dry, more supportive environment, there is less distortion of the hoof capsule, but there are more posture changes that cause coronet band distortion and bone remodeling inside the capsule. Alice also pointed out that you can safely dress off more foot in a dry rather than wet environment. A "shadow line" under the quarters of the foot shows hoof capsule collapse. Usually on these feet the posture is affected and the toe distorts forward and thickens, the sole flattens out, and if the horse is sore at the toe, bone remodeling may be happening within the capsule. Be sure the heel isn't too long, and take out the kink of the quarter with the trim. If this condition continues, the capsule may entirely break down and result in a toe crack, quarter crack, or white line disease. "I am really not into kinky shoes!" joked Alice. Rather than leave a kink in the pattern of the hoof and shoe, Alice prefers to trim excess length that produces the flares and remove the kinks. Alice prefers leaving hoof wall rather than excessively dressing it, correcting the cause of the distortion and allowing the foot to correct itself. She quoted from Mike Savoldi's research regarding heel length, that excess heel length is a common source of breakdown and that the moist line of the living sole is a reliable benchmark for trimming. Sometimes a foot appears to have no heel at all, but actually the bulb is pulled down behind. If the heel is left too high, the toe bears the load and the foot can have remodeling and flattening of the bone at the toe. Alice suggested a Lilly pad and wet poultice overnight for particularly difficult feet, and re-trimming and shoeing the horse the next day to allow the foot to fully settle. "I used to pride myself on a job done quickly and efficiently, and then I realized that maybe speed in shoeing somewhat defeats the purpose. In a longer, slower-paced shoe job, the foot is allowed to relax and the hairline may drop, allowing me to alter the trim once the foot settles. This is especially true in a wet environment." Racetrack and hunter/jumper farrier Don Reed did a live demonstration on how he applies glue-on shoes with Thoro-grip at the track on foals and on hunter/jumpers with damaged walls. Wearing his super-efficient respirator/ventilator and rubber gloves, he resembled a frogman from the U.S. Navy Seals unit. Don explained that with all the shoeing Thoroughbreds go through at the racetrack, along with the fact that they have very thin walls, often their walls cannot hold up to any more nailing. That is where he and his $300 glue-on procedure come in-for two front shoes, that is. And the adhesive only adheres to aluminum shoes, not steel. Preparation of both the foot and shoe are imperative, and strict procedures must be followed in order to accomplish the task, including cooling both the glue and the shoe on a warm day so it won't set up too fast. Don recommends using glue-on shoes a time or two, then going back to nailed-on shoes as soon as the wall growth allows. If you have any questions for Don regarding this application, feel free to call him at (626) 305-9114.

Don then went on to demonstrate his method of patching a quarter crack using

a dremel tool, a drill, and copper or stainless wire laces. "You have to

be a little bit creative," said Don, with a smile. "A patch must never be

applied to a moist, weeping crack." With over 30 years of shoeing experience,

including Santa Anita, Hollywood Park, Del Mar, Los Alamitos, and Bay Meadows

for some of the most successful trainers at these racetracks, Don had no

shortage of colorful stories, evoking occasional giggles from the crowd.

He told us of his mentor, Dude Best, who had 52 years of experience shoeing

harness horses when Don and he teamed up together, back when Don was just

18 years old. One of the most valuable things Dude passed on to Don was a

library of practical and unique solutions to horse hoof problems. Harness

horses have their own idiosyncrasies and they represent some of the most

difficult feet to hold together, due to the nature of harness racing.

Image: Myron McLane showing how to measure his full support pad. Myron McLane gave a very informative slide presentation and lecture. Myron emphasized that the walk is the only gait possible to really see a foot land. He suggested having the horse walk towards you, and viewing how the foot loads. Trim the foot to land flat, which also usually makes the coronet band parallel to the ground. If the foot is deficient on the medial or lateral side, and asymmetrical, shoe the foot full to make up for the defect. Myron also presented instruction on how to apply his new full-support pad, which stemmed from two years of searching for something easier to apply than a heart bar shoe, but would still support the bony column. To use, hold the pad up to the foot, allowing 3/8" from the apex of the frog to the tip of the frog support, trace the foot onto the pad and cut. Then add the shoe, and you have full support equal to that of a heart bar shoe. If need be, you can cut out more of the pad with a Roto Zip tool. The design of the pad allows the horse owner to get in and clean under the frog support. The horses love it, and Myron has made the application of a heart bar-style shoeing system easier for all of us to use! "Hind leg foot lameness goes undiagnosed all the time," lamented Myron. "When shoeing low-heeled hind feet, you must keep the frog on the ground." Myron suggested a thin hind shoe with a muled heel, not as a trailer but as a long-fitting shoe, allowing the frog to make ground contact. Be sure not to compress the frog with the shoe; you can hammer out a small "pocket" for the frog to sit in when the shoe is hot. Set back the shoe slightly to safe it so that if the horse overreaches, he won't hit with the shoe, but rather with the hoof itself. Myron prefers a rockered toe on the hinds to a square toe, as he feels a square toe causes the hock more strain. Myron is opposed to using an egg bar on the hind feet, as the egg bar shortens stride and stops the foot early. He also feels the egg bar causes the toe to smack at speed, as it causes a heel-first landing. In horses with suspensory problems, egg bars behind exacerbate the problem, and should not be used. Also, never raise the heels on these suspensory-problem horses; rather, lower the heels to take off the strain. Myron mentioned quarter cracks. After debriding the crack thoroughly, he suggested treating with sugardine (sugar and betadine mixed together to be thick or thin, depending on what consistency you want). This treatment will allow granulation in about 48 hours. Leave the sugardine on and the crack open for one to two weeks to heal before repairing. When shoeing a quarter crack, Myron suggested shoeing with a heart bar shoe or his full support pad, and floating the entire crack by nipping the wall shorter from the crack back to the heel.

In his demonstration in the arena, Myron smacked a dissected hoof against

the soft arena soil. He pointed out that you can hear the hoof make a flat

landing with a nice, crisp plop sound. "Some horses can't or won't land flat,

due to conformation, but the idea is to get them as flat as you can. Perhaps

a lateral extension to the shoe could help." Myron shod the foot with a steel

heart bar shoe and then his full support pad, showing how to use both.

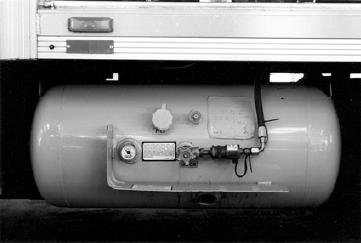

Image: One of the copper horseshoes made by Myron McLane and used by the carriage horse at Myron McLane's daughter's wedding Myron also showed us one of the copper horseshoes he made by hand for the carriage horse employed at his daughter's wedding. "Copper is the opposite of steel; when you hammer it cold, it becomes harder. When you quench it, it becomes soft," he explained. The shoes traveled six miles on the drive to the church and back. Then Myron pulled them and put them on display at the wedding reception. Quite a fitting tribute from Myron to his daughter. As the shoe circulated the arena, you could hear comments on how the shoes were remarkably heavy, although Myron commented how soft and flexible they were, compared to steel. "At one point I watched the horse spring a heel, put his foot down and the heel sprung right back up again! It was amazing." Jim Halverson spoke about propane safety (see the end of this article). Having been in a propane accident that landed him in a hospital and caused him to lose a month of work, Jim has made it his mission to increase propane safety awareness among farriers. Jim emphasized that the small barbecue propane canisters most of us use are not safe to be transported in vehicles. Rather, he suggests, go to a shop that specializes in recreational vehicles or motor fuel conversion. These folks have schematics for welding a Department of Transportation-approved propane tank to the frame of your vehicle, which meets safety requirements, for about $700. This includes high-pressure hoses, bulkhead fittings, and a new valve mandatory in California that requires shutoff at 20% below full level. On a hot day, your tank can vent as the temperature rises, so it should never be filled beyond 80%. Don't find yourself like Jim Keith, who in 1988 had a propane explosion that caused $120,000 in medical bills, loss of work for a year, and sent his horseshoes raining from the sky up to a mile away from the explosion site!

Jim Halverson also showed us his modern, efficient farrier rig, a result

of years of "industrial espionage"-gleaning ideas from the other rigs he'd

seen. "My rig allows me to open up the doors and go right to work," he explains.

"I am constantly looking at the way I do things and tearing them apart to

see if I can do things more efficiently." His rig includes three drill presses,

a belt grinder, a Swan forge with air-cooling ventilation system made from

a bilge blower, bumper-mounted anvil, and much, much more. Jim feels that

this ultra-efficient rig is a prerequisite to being a working farrier. When

asked the question: "What if you are just starting out and cannot afford

a rig like that?" Jim answered in the wink of an eye, "Get a loan and go

buy one. Even a used rig will work. Without one, your chances of failure

are greater."

Image: Contestant Aaron Wilson of Covina, California, adding to the symphony at the NCC Which brings us to the lecture by businessman Nigel Starkey, who is fairly new to farriery, but seasoned in business. "Get to know your banker," suggests Nigel. "I take my bank manager out to lunch every month. Now I'm more than a client, I'm a friend." According to Nigel, "It is always better to use other people's money to buy things. You can make money off the money you've borrowed." Nigel is a strong proponent of catastrophic insurance, which is offered by insurance companies such as Mutual Life Company as well as others and can run as low as $16 per month. In case of injury or illness, the coverage pays your wages based on last year's tax return. Not a bad idea, considering the risk of injury in our line of work. Nigel was full of ideas, including selling products from the back of one's truck, such as hoof preparations, nutritional supplements, wormers and fly spray. He suggested offering mini-clinics at stables and barns where you demonstrate your work and answer questions, and stressed the importance of keeping up with your education both by attending clinics and events, and educating your clients by printing up flyers relating to keeping their horses sound. "Perception is everything," concluded Nigel. "Have your money generate more money for you by having as many sources of income as you can. Use your personality, tell a joke, sell yourself and other products." To finish off the business tips, Bob Smith of Pacific Coast Horseshoeing School added his ideas from the book by Michael Gerber, The E-Myth Revisited. Most farriers have no plan, and live their lives by accident. He stressed the importance of purposefully planning your life so you can be sure to get where you want to go. Bob stumbled into horseshoeing on the way to law school, and stuck with it. He values education above all else, and having served in the teaching end of our industry, sees a need for what he calls "externship" programs for new farriers in the industry. There are advantages to incorporating an "extern," such as bookkeeping and liability, and anyone interested in learning more can contact Bob at (916) 366-6064. In addition to the contest and lectures, Ada Gates Patton ran the WSFA auction again this year and raised close to $15,000 for the association. The banquet was delicious, and the NCC delivered on its promise once again of being a "Classic." Next year's event will be held May 15-18, 2002 in Placerville, California. Bring the family, and yes, don't forget the swim trunks! Return to the September 2001 Table of Contents Return to the Farriers Articles Page

|